Color motion picture film: Difference between revisions

→External link: link to AWM's specific page of color processes |

→External link: changed external link to wikilink |

||

| Line 83: | Line 83: | ||

==External link== |

==External link== |

||

* The [ |

* The [[American Widescreen Museum]] has a thorough treatise on [http://www.widescreenmuseum.com/oldcolor/index.htm early motion picture color processes]. |

||

[[Category:Film and video technology]][[Category:Photographic films]] |

[[Category:Film and video technology]][[Category:Photographic films]] |

||

Revision as of 13:44, 19 September 2006

This article discusses the evolution and technology behind color photographic film, with specific focus on motion pictures.

History of Color film

For the history of motion picture film, in general, see 35 mm film

Color movies started nearly as early as film itself in 1895 with Thomas Edison's hand-painted Anabelle's Dance made for his Kinetoscope viewers. George Méliès was utilizing a similar hand-painting process for his films, including the early pioneer A trip to the Moon (1902), which had various parts of the film painted frame-by-frame by twenty-one women in Montreuil[1] in a production-line method.[2] Between 1900 and 1935, dozens of color systems were introduced, some successfully.[3]

Among the early dye-coloring processes, Pathé Frères invented Pathé Color (renamed Pathéchrome in 1929), one of the most accurate and reliable stencil coloring systems that incorporated a series of glass stencils, cut by pantograph to correspond to those areas to be tinted in any one of six standard colors[1] by a coloring machine with dye-soaked, velvet rollers to color films.[4] After a stencil had been made for the whole film, it was placed into contact with the print to be colored and run at high speed (60 feet per minute) through the coloring (staining) machine. The process was repeated for each set of stencils corresponding to a different color. By 1910 Pathé had over 400 women employed as stencilers in their Vincennes factory. Pathéchrome continued in production through the 1930s.[1]

A more common technique, Film tinting is a process in which either the emulsion or the film base are dyed, giving the image a uniform monochromatic color. This process was popular during the 1920s with specific colors employed for certain narrative effects (red for scenes with fire or firelight, blue for night, etc.).[2]

A complementary process, called toning, replaces the silver halide particles in the film with metallix salts or mordanted dyes. This creates a color effect in which the dark parts of the image are replaced with a color (eg. blue and white rather than black and white). Tinting and toning were sometimes applied together.[2]

Eastman Kodak introduced their own system of pre-tinted black-and-white film stocks called Sonochrome in 1929. Sonochrome featured films tinted in sixteen different colors including: Peachblow, Inferno, Rose Doree, Candle Flame, Sunshine, Purple Haze, Firelight, Fleur de Lis, Azure, Nocturne, Verdante, Aquagreen, Caprice and the neutral density "Argent", which kept the screen from becoming excessively bright when switching to a black and white scene.[3]

Physics of light and color

The principles on which color photography are based were first proposed by Scottish physicist James Clerk Maxwell in 1855 and finally presented at the Royal Institution of London in 1861. By this time, it was known that light is comprised of a spectrum of different wavelengths which are perceived as different colors as they are absorbed and reflected by natural objects. Maxwell discovered that all natural colors in this spectrum are composed of different combinations of three primary colors - red, green and blue - which when mixed together equally produce white light.[1]

Additive color

The additive color systems were practical because they could be incorporated with black-and-white film stock. The various additive systems entailed the use of color filters on both the photography and projection apparatus. Additive color adds lights of the primary colors in various proportions to the projected image. Because of the limited amount of space to record images on film, and later because the lack of a camera that could record more than two strips of film at once, most early motion picture color systems consisted of two colors, often red and green or red and blue.

Practical color in the motion picture business began with Kinemacolor, first introduced in 1906,[4] a two-color system created in England by Edward R. Turner and George Albert Smith. It was used for a series of films including the documentary The Durbar at Delhi (1912). In Kinemacolor, alternating frames of specially sensitized black-and-white film were photographed at 32 frames per second through either the red or green areas of a rotating filter, and the printed film was projected through the same filter at the same speed. The sense of color was achieved through a combination of separate red and green alternating images and the viewer's persistence of vision. [2]

Frenchman Louis Dufay developed Dufay Color in the 1930s, which was a reversal film (producing a positive image on the camera original) that used a mosaic of tiny filter elements of the primary colors between the emulsion and base of the film.[4].

By the nature of the system, additive color systems were not economical. Because of the filters used to project the films, more light was required than was projected onto the screen, resulting in an image that was dimmer than the average, black and white image. The larger the screen, the dimmer the picture would be. For this and other case-by-case reasons, additive processes for motion pictures grew less in favor about the time of the Second World War, though a variation of additive color systems are employed for all color video and computer display systems.[2]

Subtractive color

After experimenting with more advanced methods of additive systems (including a camera with two apertures (one with a red filter one with green)) Dr. Herbert T. Kalmus and Dr. Donald F. Comstock developed the subtractive color system for Technicolor by utilizing a beam splitter in a specially modified camera to send red and green light waves to separate film negatives. From these negatives two prints were made on film stock with half the base thickness than normal, which were toned accordingly - one red the other green[4]. Then they were cemented together base-to-base into a single strip of film. The first film using this process was Toll of the Sea (1922). Perhaps the most ambitious film made with this process was The Black Pirate, directed by Albert Parker (1926). The system was refined through the incorporation of dye imbibition, which allowed for the transferring of dyes from both color matrices into a single print - thus avoiding the problems at attaching two prints back-to-back and allowing for multiple prints to be created from a single pair of matrices.[2]

Technicolor's system was extremely popular for a number of years, but it was a very expensive process: shooting cost three times that of black and white photography and printing costs were no cheaper. By 1932, general color photography had nearly been abandoned by major studios, until Technicolor developed a new advancement to record all three, primary colors. Utilizing a special dichroic beam splitter equipped with two 45-degree prisms in the form of a cube, light from the lens was deflected by the prisms and split into two paths to expose each one of three black and white negatives (one each to record the densities for red, green, and blue).

The three negatives were then printed to gelatin "matrices" which also completely bleached the image, washing out the silver and leaving only the gelatin record of the image. A "receiver print", consisting of a 50% density print of the black and white negative for the green record strip, and including the soundtrack, was struck and treated with dye mordants to aid in the imbibition process (this "black" layer was discontinued in the early 1940s). The matrices for each strip were coated with their complementary dye (yellow, cyan, or magenta), and then each successively brought into high-pressure contact with the receiver, which would imbibe and hold the dyes which collectively were able to render a wider spectrum of colors than the previous technologies.[5] The first film with the three-color (also called three-strip) system was the short film La Cucaracha (1934); the first feature was Becky Sharp (1935).[4] These films and their prints have extremely high long-term sustainability because both the black and white negatives and the dye-based prints are very resistant to fading, unlike modern one-strip color films which eventually fade towards pink as the dye couplers continue to chemically degrade over time. In order to counteract this inevitable process with modern color films, the three-strip process is essentially reverse engineered to create separation masters, which are three black and white negatives, one each sensitized for red, green, and blue, that can be reliably used to preserve the color record of modern films.

Monopack color film

Modern color film is based on the subtractive color system, which filters colors from white light through dyed or color sensitive layers within a single strip of film. A subtractive color (cyan, magenta, yellow) is what remains when one of the additive primary colors (red, green, blue) has been removed from the spectrum. Eastman Kodak's tripack color film incorporated three separate layers of color sensitive emulsions into one strip of film. Kodachrome was the first commercially successful application of monopack multilayer film, introduced in 1935.[6]

Eastmancolor, introduced in 1952, was Kodak's first, economical, single-strip 35 mm negative recording system, incorporated into one strip of film. This rendered the three-strip photography relatively obsolete, even though for the first few years, Technicolor's quality control in printing produced colors that were more precise than monopack film and the dye-transfer print would maintain its color much longer than an Eastman print, which would fade over time, mostly due to poor processing and improper storage.[3]

Technicolor continued to offer the dye-imbibition print process for projection prints until 1975, and even briefly revived it in 1998. As an archival format, Technicolor prints are one of the most stable color print processes yet created, and prints properly cared for are estimated to retain their color for centuries.[7] With the introduction of low-fade (LPP) films, properly stored (at 45oF and 25 per cent relative humidity) monopack color film is expected to last, with no fading, a comparative amount of time. Kodachrome tranparency film stored at 0oF is predicted to last a similar length in time without noticeable picture degradation. Improperly stored monopack color film from before 1983 can incur a 30 per cent image loss in as little as 25 years.[8]

How modern color film works

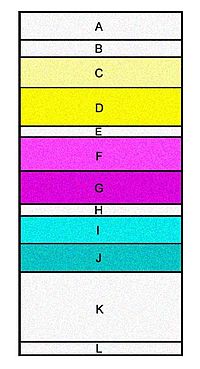

Modern color film is made up of many different layers all working together to create the color image. In color negative films there are three main color layers: the blue record, green record and red record; each made up of two separate layers. Each layer contains silver halide crystals and dye-couplers. A cross-sectional representation of a piece of developed color negative film is at right. Each layer of the film is so thin that the composite of all layers, in addition to the triacetate base and antihaliation backing, is less than .0003" thick.[9]

The three color records are stacked as shown at right with a UV filter on top to keep the non-visible ultraviolet radiation from exposing the silver halide crystals, which are naturally sensitive to UV light. Next, the fast and slow blue sensitive layers, which, when developed, form the latent image. When the exposed silver halide crystal is developed, it is coupled with a dye grain of its complementary color. This forms a dye "cloud" (like a drop of water on a paper towel) and is limited in its growth by developing ingibiting releasing (DIR) couplers, which also serve to refine the sharpness of the processed image by limiting the size of the dye clouds. The dye clouds formed in the blue layer are actually yellow (the opposite or complimentary color to blue).[10] There are two layers to each color; a "fast" and a "slow." The fast layer features larger grains that are more sensitive to light than the slow layer, which has finer grain and is less sensitive to light. Silver halide crystals are naturally sensitive to blue light, so the blue layers are on the top of the film and they are followed immediately by a yellow filter, which stops any more blue light from passing through to the green and red layers and biasing those crystals with extra blue exposure. Next are the red sensitive record (which forms cyan dyes when developed), and at the bottom, the green sensitive record, which forms magenta dyes when developed. Each color is separated by a gelatin layer which prevents silver development in one record from causing unwanted dye formation in another. The bottom of the whole stack (film base) is an antihaliation layer that prevents bright light from reflecting off the clear base of the film and passing back through the negative to double-expose the crystals and create "halos" of light around bright spots. In color film this backing is rem-jet, which is a black-pigmented non-gelatin layer on the back of the film base and is removed in the developing process.[9]

Eastman Kodak manufacturers film in 54 inch wide rolls. These rolls are then slit into various sizes (65 mm, 35 mm, 16 mm) as needed.

Modern manufacturers of color film for motion picture use

See also List of motion picture film stocks

Motion picture film, primarily because of the rem-jet backing, requires a different developer bath than standard color film. The developer necessary is ECN-2 (Eastman Color Negative 2). If motion picture negative is run through a standard C-41 color film developer bath, the rem-jet backing will destroy the intregrity of the developer and, potentially, ruin the film.

There are two main companies manufacturing color film for motion picture use: Eastman Kodak and Fuji Films.

Kodak color motion picture films

In the late 1980s Kodak introduced the T-Grain emulsion, a technological advancement in the shape and makeup of silver halide grains in their films. T-Grain is a tabular silver halide grain that allows for greater overall surface area, resulting in greater light sensitivity with a relatively small grain and a more uniform shape which results in a less overall graininess to the film. This made for sharper and more sensitive films. The T-Grain technology was first employed in Kodak's EXR line of motion picture color negative stocks.[11] This was further refined in 1996 with the Vision line of emulsions, followed by Vision2 in the early 2000s.

Fuji color motion picture films

Fuji films also integrate tabular grains in their SUFG (Super Unified Fine Grain) films. In their case the SUFG grain is not only tabular, it is hexagonal and consistent in shape throughout the emulsion layers. Like the T-grain, it has a larger surface area in a smaller grain (about 1/3 the size of traditional grain for the same light sensitivity. In 2005 Fuji unveiled their Eterna 500T stock, the first in a new line of advanced emulsions, keeping competitive with Kodak's innovations.

References

- ^ a b c d Cook, David A. (1990) (2nd ed). A History of Narrative Film W. W. Norton & Company. ISBN 0-393-95553-2.

- ^ a b c d e f Konigsberg, Ira (1987). The Complete Film Dictionary Meridan PAL books. ISBN 0-452-00980-4.

- ^ a b c Monaco, James (1981) (Revised ed) How to Read a Film Oxford University Press. ISBN 0-19-502806-6.

- ^ a b c d e Katz, Ephraim (1994) (2nd ed). The Film Encyclopedia HarperCollins Press. ISBN0-06-273089-4

- ^ Hart, Martin (2003). "The History of Technicolor" Retrieved July 7, 2006.

- ^ Exploring the Color Image (1996) Eastman Kodak Publication H-188.

- ^ Wilhelm, Henry with Brower, Carol (1993) The Permanence and Care of Color Photographs. Preservation Publishing Company. Chapter 10 "The Extraordinarily Stable Technicolor Dye Imbibition Motion Picture Color Print Process" pp. 345-366

- ^ Holben, Jay (June 1999). "Preserving Negatives for the Next Generation" American Cinematographer Magazine ASC Press. pp. 147-152.

- ^ a b Kodak Motion Picture Film (H1) (4th ed). Eastman Kodak Company. ISBN 0-87985-477-4

- ^ Holben, Jay. (April 2000). "Taking Stock" Part 1 of 2. American Cinematographer Magazine ASC Press. pp. 118-130

- ^ Probst, Christopher. (May 2000). "Taking Stock" Part 2 of 2 American Cinematographer Magazine ASC Press. pp. 110-120

See also

- 135 film

- 35 mm film

- Color photography

- Film base

- Photographic film

- Technicolor

- Cinecolor

- Multicolor

- Kinemacolor

External link

- The American Widescreen Museum has a thorough treatise on early motion picture color processes.