Sophorolipid

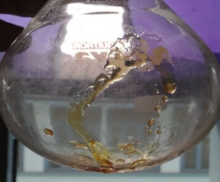

A sophorolipid is a surface-active glycolipid compound that can be synthesized by a selected number of non-pathogenic yeast species.[1] They are potential bio-surfactants due to their biodegradability and low eco-toxicity.

Structure and properties

Sophorolipids are glycolipids consisting of a hydrophobic fatty acid tail of 16 or 18 carbon atoms and a hydrophilic carbohydrate head sophorose, a glucose-derived di-saccharide with an unusual β-1,2 bond and can be acetylated on the 6′- and/or 6′′- positions. One terminal or sub terminal hydroxylated fatty acid is β-glycosidically linked to the sophorose module. The carboxylic end of this fatty acid is either free (acidic or open form) or internally esterified at the 4′′ or in some rare cases at the 6′- or 6′′-position (lactonic form).[2] The physicochemical and biological properties of sophorolipids are significantly influenced by the distribution of the lactone vs. acidic forms produced in the fermentative broth. In general, lactone sophorolipids are more efficient in reducing surface tension and are better antimicrobial agents, whereas acidic sophorolipids display better foaming properties. Acetyl groups can also lower the hydrophilicity of sophorolipids and enhance their antiviral and cytokine stimulating effects.[3]

Sophorolipids are produced by various non pathogenic yeast species such as Candida apicola, Rhodotorula bogoriensis,[5] Wickerhamiella domercqiae,[6] and Starmerella bombicola.[7][8] Recent research has meant sophorolipids can be recovered during a fermentation using a gravity separator in a loop with the bioreactor, enabling the production of >770 g/L sophorolipid at a productivity 4.24 g/L/h, some of the highest values seen in a fermentation process [9] Desirable properties of biosurfactants are biodegradability and low toxicity.[10][11] Sophorolipids produced by several yeasts belonging to candida and the starmerella clade,[12][13] and Rhamnolipid produced by Pseudomonas aeruginosa[14] etc.

Besides biodegradability, low toxicity, and high production potential, sophorolipids have a high surface and interfacial activity. Sophorolipids are reported to lower surface tension (ST) of water from 72 to 30-35 mN/m and the interfacial tension (IT) water/hexadecane from 40 to 1 mN/m.[15] In addition to this, sophorolipids are reported to function under wide ranges of temperatures, pressures and ionic strengths; and they also possess a number of other useful biological activities including Antimicrobial,[5] virucidal,[3] Anticancer, Immuno-modulatory properties.[5]

Research

A detailed and comprehensive literature review on the various aspects of sophorolipids production (e.g. producing micro-organisms, bio-synthetic pathway, effect of medium components and other fermentation conditions and downstream process of sophorolipids is available in the published work of Van Bogaert et al.[5][16] This work also discusses potential application of sophorolipids (and their derivatives) as well as the potential for genetic engineering strains to enhance sophorolipid yields. Researchers have focused on optimization of sophorolipid production in submerged fermentation,[17][18] but some efforts have also investigated the possibility of sophorololipid production using solid state fermentation (SSF).[4] The production process can be significantly impacted by the specific properties of the carbon and oil substrates used; and several inexpensive alternatives to more traditional substrates have been investigated. These potential substrates include: biodiesel by-product streams,[19] waste frying oil,[20][21] restaurant waste oil,[22] industrial fatty acid residues,[23] mango seed fat,[24] and soybean dark oil. The use of most of these substrates have resulted in lower yields compared to traditional fermentation substrates.

Chemical modifications of sophorolipids, and polysophorolipids

To enhance the performance of surfactant properties of natural sophorolipids, chemical modification methods have been actively pursued.[25] Recently, researchers demonstrated the possibility of applying sophorolipids as building blocks via ring-opening metathesis polymerization for a new type of polymers, known as polysophorolipids which show promising potentials in biomaterials applications.[26]

References

- ^ Ribeiro, Isabel; Castro, Matilde; Ribeiro, Maria (2013). "Sophorolipids". Applications of Microbial Engineering. pp. 367–407. doi:10.1201/b15250-15. ISBN 978-1-4665-8577-5.

- ^ Davila, A.-M.; Marchal, R.; Vandecasteele, J.-P., Sophorose lipid production from lipidic precursors: Predictive evaluation of industrial substrates. Journal of Industrial Microbiology 1994, 13 (4), 249-257.

- ^ a b Shah, V.; Doncel, G. F.; Seyoum, T.; Eaton, K. M.; Zalenskaya, I.; Hagver, R.; Azim, A.; Gross, R., Sophorolipids, microbial glycolipids with anti-human immunodeficiency virus and sperm-immobilizing activities. Antimicrob Agents Chemother 2005, 49 (10), 4093-4100.

- ^ a b Parekh, V. J.; Pandit, A. B., Solid State Fermentation (SSF) for the Production of Sophorolipids from Starmerella bombicola NRRL Y-17069 using glucose, wheat bran and oleic acid. Current Trends in Biotechnology and Pharmacy 2012, 6 (4), 418-424.

- ^ a b c d Van Bogaert, I. N. A.; Zhang, J.; Soetaert, W., Microbial synthesis of sophorolipids. Process Biochemistry 2011, 46 (4), 821-833

- ^ Chen, J.; Song, X.; Zhang, H.; Qu, Y. B.; Miao, J. Y., Sophorolipid produced from the new yeast strain Wickerhamiella domercqiae induces apoptosis in H7402 human liver cancer cells. Applied Microbiology and Biotechnology 2006, 72 (1), 52-59.

- ^ Kurtzman, C. P.; Price, N. P.; Ray, K. J.; Kuo, T. M., Production of sophorolipid biosurfactants by multiple strains of the Starmerella (Candida) bombicola yeast clade. FEMS Microbiol Lett 2010, 311 (2), 140-146.

- ^ Parekh, V. J.; Pandit, A. B., Optimization of fermentative production of sophorolipid biosurfactant by starmerella bombicola NRRL Y-17069 using response surface methodology. International Journal of Pharmacy and Biological Sciences 2011, 1 (3), 103-116

- ^ B.Dolman, C.Kaisermann et al. Integrated sophorolipid production and gravity separation, Process Biochemistry 2017, 54, 162-171.

- ^ Deleu, M.; Paquot, M., From renewable vegetables resources to microorganisms: new trends in surfactants. Comptes Rendus Chimie 2004, 7 (6–7), 641-646

- ^ Mohan, P. K.; Nakhla, G.; Yanful, E. K., Biokinetics of biodegradation of surfactants under aerobic, anoxic and anaerobic conditions. Water Research 2006, 40 (3), 533-540

- ^ Kurtzman CP, Price NP, Ray KJ, Kuo TM (October 2010). "Production of sophorolipid biosurfactants by multiple species of the Starmerella (Candida) bombicola yeast clade". FEMS Microbiol. Lett. 311 (2): 140–6. doi:10.1111/j.1574-6968.2010.02082.x. PMID 20738402.

- ^ Parekh, V. J.; Pandit, A. B. (2011). "Optimization of fermentative production of sophorolipid biosurfactant by starmerella bombicola NRRL Y-17069 using response surface methodology". International Journal of Pharmacy and Biological Sciences. 1 (3): 103–116.

- ^ Ito S, Honda H, Tomita F, Suzuki T (December 1971). "Rhamnolipids produced by Pseudomonas aeruginosa grown on n-paraffin (mixture of C 12 , C 13 and C 14 fractions)". J. Antibiot. 24 (12): 855–9. doi:10.7164/antibiotics.24.855. PMID 4334639.

- ^ Cooper, D. G.; Paddock, D. A., Production of a Biosurfactant from Torulopsis bombicola. Appl Environ Microbiol 1984, 47 (1), 173-176.

- ^ Van Bogaert I (2008) Microbial synthesis of sophorolipids by the yeast Candida bombicola. PhD-thesis, Faculty of Bioscience Engineering, Ghent University, Ghent, Belgium, 239 p

- ^ Parekh, V. J.; Pandit, A. B., Optimization of fermentative production of sophorolipid biosurfactant by starmerella bombicola NRRL Y-17069 using response surface methodology. International Journal of Pharmacy and Biological Sciences 2011, 1 (3), 103-116.

- ^ Rispoli, F. J.; Badia, D.; Shah, V., Optimization of the fermentation media for sophorolipid production from Candida bombicola ATCC 22214 using a simplex centroid design. Biotechnology Progress 2010, 26 (4), 938-944.

- ^ Ashby, R.; Nuñez, A.; Solaiman, D. Y.; Foglia, T., Sophorolipid biosynthesis from a biodiesel co-product stream. Journal of the American Oil Chemists' Society 2005, 82 (9), 625-630.

- ^ Fleurackers, S. J. J., On the use of waste frying oil in the synthesis of sophorolipids. European Journal of Lipid Science and Technology 2006, 108 (1), 5-12.

- ^ Wadekar, S.; Kale, S.; Lali, A.; Bhowmick, D.; Pratap, A., Sophorolipid production by starmerella bombicola (ATCC 22214) from virgin and waste frying oils, and the effects of activated earth treatment of the waste oils. JAOCS, Journal of the American Oil Chemists' Society 2012, 89 (6), 1029-1039.

- ^ Shah, V.; Jurjevic, M.; Badia, D., Utilization of restaurant waste oil as a precursor for sophorolipid production. Biotechnol Prog 2007, 23 (2), 512-515.

- ^ Ashby, R. D.; Solaiman, D. K.; Foglia, T. A., The use of fatty acid esters to enhance free acid sophorolipid synthesis. Biotechnol Lett 2006, 28 (4), 253-260.

- ^ Parekh, V. J.; Patravale, V. B.; Pandit, A. B., Mango kernel fat: A novel lipid source for the fermentative production of sophorolipid biosurfactant using Starmerella Bombicola NRRL-Y 17069. Annals of Biological Research 2012, 3 (4), 1798-1803.

- ^ "DSM enters into agreement with SyntheZyme LLC for Production of Surfactants".

- ^ Peng, Yifeng; Munoz-Pinto, Dany J.; Chen, Mingtao; Decatur, John; Hahn, Mariah; Gross, Richard A. (10 November 2014). "Poly(sophorolipid) Structural Variation: Effects on Biomaterial Physical and Biological Properties". Biomacromolecules. 15 (11): 4214–4227. doi:10.1021/bm501255j.