Pendulum clock

A pendulum clock is a clock that uses a pendulum, a swinging weight, as its timekeeping element. The advantage of a pendulum for timekeeping is that it is an approximate harmonic oscillator: It swings back and forth in a precise time interval dependent on its length, and resists swinging at other rates. From its invention in 1656 by Christiaan Huygens, inspired by Galileo Galilei, until the 1930s, the pendulum clock was the world's most precise timekeeper, accounting for its widespread use.[1][2] Throughout the 18th and 19th centuries, pendulum clocks in homes, factories, offices, and railroad stations served as primary time standards for scheduling daily life, work shifts, and public transportation. Their greater accuracy allowed for the faster pace of life which was necessary for the Industrial Revolution.[3]: p.623 The home pendulum clock was replaced by less-expensive synchronous electric clocks in the 1930s and 1940s. Pendulum clocks are now kept mostly for their decorative and antique value.

Pendulum clocks must be stationary to operate. Any motion or accelerations will affect the motion of the pendulum, causing inaccuracies, so other mechanisms must be used in portable timepieces.

History

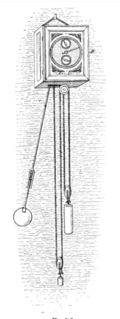

The pendulum clock was invented on 25 December 1656 by Dutch scientist and inventor Christiaan Huygens, and patented the following year. He described it in his manuscript Horologium published in 1658.[4] Huygens contracted the construction of his clock designs to clockmaker Salomon Coster, who actually built the clock.[4] Huygens was inspired by investigations of pendulums by Galileo Galilei beginning around 1602. Galileo discovered the key property that makes pendulums useful timekeepers: they are isochronic, which means that the period of swing of a pendulum is approximately the same for different sized swings.[5][6] Galileo in 1637 described to his son a mechanism which could keep a pendulum swinging, which has been called the first pendulum clock design (picture at top). It was partly constructed by his son in 1649, but neither lived to finish it.[4][7] The introduction of the pendulum, the first harmonic oscillator used in timekeeping, increased the accuracy of clocks enormously, from about 15 minutes per day to 15 seconds per day[8] leading to their rapid spread as existing 'verge and foliot' clocks were retrofitted with pendulums. By 1659 pendulum clocks were being manufactured in France by clockmaker Nicolaus Hanet, and in England by Ahasuerus Fromanteel.[4]

These early clocks, due to their verge escapements, had wide pendulum swings[4] of 80–100°. In his 1673 analysis of pendulums, Horologium Oscillatorium, Huygens showed that wide swings made the pendulum inaccurate, causing its period, and thus the rate of the clock, to vary with unavoidable variations in the driving force provided by the movement.[4] Clockmakers' realization that only pendulums with small swings of a few degrees are isochronous motivated the invention of the anchor escapement by Robert Hooke around 1658,[4] which reduced the pendulum's swing to 4–6°.[9] The anchor became the standard escapement used in pendulum clocks. In addition to increased accuracy, the anchor's narrow pendulum swing allowed the clock's case to accommodate longer, slower pendulums, which needed less power and caused less wear on the movement. The seconds pendulum (also called the Royal pendulum), 0.994 m (39.1 in) long, in which the time period is two seconds, became widely used in quality clocks. The long narrow clocks built around these pendulums, first made by William Clement around 1680, who also claimed invention of the anchor escapement,[4] became known as grandfather clocks. The increased accuracy resulting from these developments caused the minute hand, previously rare, to be added to clock faces beginning around 1690.[10][4]

The 18th and 19th century wave of horological innovation that followed the invention of the pendulum brought many improvements to pendulum clocks.[3]: p.624 The deadbeat escapement invented in 1675 by Richard Towneley and popularized by George Graham around 1715 in his precision "regulator" clocks gradually replaced the anchor escapement[11][4] and is now used in most modern pendulum clocks. Observation that pendulum clocks slowed down in summer brought the realization that thermal expansion and contraction of the pendulum rod with changes in temperature was a source of error. This was solved by the invention of temperature-compensated pendulums; the mercury pendulum by Graham in 1721 and the gridiron pendulum by John Harrison in 1726.[12][4] With these improvements, by the mid-18th century precision pendulum clocks achieved accuracies of a few seconds per week.

Until the 19th century, clocks were handmade by individual craftsmen and were very expensive.[3]: p.625 The rich ornamentation of pendulum clocks of this period indicates their value as status symbols of the wealthy. The clockmakers of each country and region in Europe developed their own distinctive styles. By the 19th century, factory production of clock parts gradually made pendulum clocks affordable by middle-class families.

During the Industrial Revolution, the faster pace of life and scheduling of shifts and public transportation like trains depended on the more accurate timekeeping made possible by the pendulum.[3]: p.624 Daily life was organized around the home pendulum clock. More accurate pendulum clocks, called regulators, were installed in places of business and railroad stations and used to schedule work and set other clocks. The need for extremely accurate timekeeping in celestial navigation to determine longitude on ships during long sea voyages drove the development of the most accurate pendulum clocks, called astronomical regulators. These precision instruments, installed in clock vaults in naval observatories and kept accurate within a fraction of a second by observation of star transits overhead, were used to set marine chronometers on naval and commercial vessels. Beginning in the 19th century, astronomical regulators in naval observatories served as primary standards for national time distribution services that distributed time signals over telegraph wires.[13] From 1909, US National Bureau of Standards (now NIST) based the US time standard on Riefler pendulum clocks, accurate to about 10 milliseconds per day. In 1929 it switched to the Shortt-Synchronome free pendulum clock before phasing in quartz standards in the 1930s.[14] [15] With an error of less than one second per year, the Shortt was the most accurate commercially produced pendulum clock.[16][17][18][19][20]

Pendulum clocks remained the world standard for accurate timekeeping for 270 years, until the invention of the quartz clock in 1927, and were used as time standards through World War II. The French Time Service included pendulum clocks in their ensemble of standard clocks until 1954.[21] The home pendulum clock began to be replaced as domestic timekeeper during the 1930s and 1940s by the synchronous electric clock, which kept more accurate time because it was synchronized to the oscillation of the electric power grid. The most accurate experimental pendulum clock ever made[22][23] may be the Littlemore Clock built by Edward T. Hall in the 1990s[24] (donated in 2003 to the National Watch and Clock Museum, Columbia, Pennsylvania, USA). The largest pendulum clocks, exceeding 30 m (98 ft), were built in Geneva (1972) and Gdańsk (2016).[25][26]

Mechanism

The mechanism which runs a mechanical clock is called the movement. The movements of all mechanical pendulum clocks have these five parts:[27]

- A power source; either a weight on a cord or chain that turns a pulley or sprocket, or a mainspring.

- A gear train (wheel train) that steps up the speed of the power so that the pendulum can use it. The gear ratios of the gear train also divide the rotation rate down to give wheels that rotate once every hour and once every 12 or 24 hours, to turn the hands of the clock.

- An escapement that gives the pendulum precisely timed impulses to keep it swinging, and which releases the gear train wheels to move forward a fixed amount at each swing. This is the source of the "ticking" sound of an operating pendulum clock.

- The pendulum, a weight on a rod, which is the timekeeping element of the clock.

- An indicator or dial that records how often the escapement has rotated and therefore how much time has passed, usually a traditional clock face with rotating hands.

Additional functions in clocks besides basic timekeeping are called complications. More elaborate pendulum clocks may include these complications:

- Striking train: strikes a bell or gong on every hour, with the number of strikes equal to the number of the hour. Some clocks will also signal the half hour with a single strike. More elaborate types, technically called chiming clocks, strike on the quarter hours, and may play melodies or Cathedral chimes, usually Westminster quarters.

- Calendar dials: show the day, date, and sometimes month.

- Moon phase dial: shows the phase of the moon, usually with a painted picture of the moon on a rotating disk. These were useful historically for people planning nighttime journeys.

- Equation of time dial: this rare complication was used in early days to set the clock by the passage of the sun overhead at noon. It displays the difference between the time indicated by the clock and the time indicated by the position of the sun, which varies by as much as ±16 minutes during the year.

- Repeater attachment: repeats the hour chimes when triggered by hand. This rare complication was used before artificial lighting to check what time it was at night.

In electromechanical pendulum clocks such as used in mechanical Master clocks the power source is replaced by an electrically powered solenoid that provides the impulses to the pendulum by magnetic force, and the escapement is replaced by a switch or photodetector that senses when the pendulum is in the right position to receive the impulse. These should not be confused with more recent quartz pendulum clocks in which an electronic quartz clock module swings a pendulum. These are not true pendulum clocks because the timekeeping is controlled by a quartz crystal in the module, and the swinging pendulum is merely a decorative simulation.

Gravity-swing pendulum

The pendulum in most clocks (see diagram) consists of a wood or metal rod (a) with a metal weight called the bob (b) on the end. The bob is traditionally lens-shaped to reduce air drag. Wooden rods were often used in quality clocks because wood had a lower coefficient of thermal expansion than metal. The rod is usually suspended from the clock frame with a short straight spring of metal ribbon (d); this avoids instabilities that were introduced by a conventional pivot. In the most accurate regulator clocks the pendulum is suspended by metal knife edges resting on flat agate (a hard mineral that will retain a highly polished surface).

The pendulum is driven by an arm hanging behind it attached to the anchor piece (h) of the escapement, called the "crutch" (e), ending in a "fork" (f) which embraces the pendulum rod. Each swing of the pendulum releases the escape wheel, and a tooth of the wheel presses against one of the pallets, exerting a brief push through the crutch and fork on the pendulum rod to keep it swinging.

Most quality clocks, including all grandfather clocks, have a "seconds pendulum", in which each swing of the pendulum takes one second (a complete cycle takes two seconds), which is approximately one metre (39 inches) long from pivot to center of bob. Mantel clocks often have a half-second pendulum, which is approximately 25 centimetres (9.8 in) long. Only a few tower clocks use longer pendulums, the 1.5 second pendulum, 2.25 m (7.4 ft) long, or occasionally the two-second pendulum, 4 m (13 ft) which is used in the Great Clock of Westminster which houses Big Ben.

The pendulum swings with a period that varies with the square root of its effective length. For small swings the period T, the time for one complete cycle (two swings), is

where L is the length of the pendulum and g is the local acceleration of gravity. All pendulum clocks have a means of adjusting the rate. This is usually an adjustment nut (c) under the pendulum bob which moves the bob up or down on its rod. Moving the bob up reduces the length of the pendulum, reducing the pendulum's period so the clock gains time. In some pendulum clocks, fine adjustment is done with an auxiliary adjustment, which may be a small weight that is moved up or down the pendulum rod. In some master clocks and tower clocks, adjustment is accomplished by a small tray mounted on the rod where small weights are placed or removed to change the effective length, so the rate can be adjusted without stopping the clock.

The period of a pendulum increases slightly with the width (amplitude) of its swing. The rate of error increases with amplitude, so when limited to small swings of a few degrees the pendulum is nearly isochronous; its period is independent of changes in amplitude. Therefore, the swing of the pendulum in clocks is limited to 2° to 4°.

Small swing angles tend toward isochronous behavior due to the mathematical fact that the approximation becomes valid as the angle approaches zero. With that substitution made, the pendulum equation becomes the equation of a harmonic oscillator, which has a fixed period in all cases. As the swing angle becomes larger, the approximation gradually fails and the period is no longer fixed.

Temperature compensation

A major source of error in pendulum clocks is thermal expansion; the pendulum rod changes in length slightly with changes in temperature, causing changes in the rate of the clock. An increase in temperature causes the rod to expand, making the pendulum longer, so its period increases and the clock loses time. Many older quality clocks used wooden pendulum rods to reduce this error, as wood expands less than metal.

The first pendulum to correct for this error was the mercury pendulum invented by Graham in 1721, which was used in precision regulator clocks into the 20th century. These had a bob consisting of a container of the liquid metal mercury. An increase in temperature would cause the pendulum rod to expand, but the mercury in the container would also expand and its level would rise slightly in the container, moving the center of gravity of the pendulum up toward the pivot. By using the correct amount of mercury, the centre of gravity of the pendulum remained at a constant height, and thus its period remained constant, despite changes in temperature.

The most widely used temperature-compensated pendulum was the gridiron pendulum invented by John Harrison around 1726. This consisted of a "grid" of parallel rods of high-thermal-expansion metal such as zinc or brass and low-thermal-expansion metal such as steel. If properly combined, the length change of the high-expansion rods compensated for the length change of the low-expansion rods, again achieving a constant period of the pendulum with temperature changes. This type of pendulum became so associated with quality that decorative "fake" gridirons are often seen on pendulum clocks, that have no actual temperature compensation function.

Beginning around 1900, some of the highest precision scientific clocks had pendulums made of ultra-low-expansion materials such as the nickel steel alloy Invar or fused silica, which required very little compensation for the effects of temperature.

Atmospheric drag

The viscosity of the air through which the pendulum swings will vary with atmospheric pressure, humidity, and temperature. This drag also requires power that could otherwise be applied to extending the time between windings. Traditionally the pendulum bob is made with a narrow streamlined lens shape to reduce air drag, which is where most of the driving power goes in a quality clock. In the late 19th century and early 20th century, pendulums for precision regulator clocks in astronomical observatories were often operated in a chamber that had been pumped to a low pressure to reduce drag and make the pendulum's operation even more accurate by avoiding changes in atmospheric pressure. Fine adjustment of the rate of the clock could be made by slight changes to the internal pressure in the sealed housing.

Leveling and "beat"

To keep time accurately, pendulum clocks must be level. If they are not, the pendulum swings more to one side than the other, upsetting the symmetrical operation of the escapement. This condition can often be heard audibly in the ticking sound of the clock. The ticks or "beats" should be at precisely equally spaced intervals to give a sound of, "tick...tock...tick...tock"; if they are not, and have the sound "tick-tock...tick-tock..." the clock is out of beat and needs to be leveled. This problem can easily cause the clock to stop working, and is one of the most common reasons for service calls. A spirit level or watch timing machine can achieve a higher accuracy than relying on the sound of the beat; precision regulators often have a built-in spirit level for the task. Older freestanding clocks often have feet with adjustable screws to level them, more recent ones have a leveling adjustment in the movement. Some modern pendulum clocks have 'auto-beat' or 'self-regulating beat adjustment' devices, and do not need this adjustment.

Local gravity

Since the pendulum rate will increase with an increase in gravity, and local gravitational acceleration varies with latitude and elevation on Earth, the highest precision pendulum clocks must be readjusted to keep time after a move. For example, a pendulum clock moved from sea level to 4,000 feet (1,200 m) will lose 16 seconds per day.[28] With the most accurate pendulum clocks, even moving the clock to the top of a tall building would cause it to lose measurable time due to lower gravity.[29] The local gravity also varies by about 0.5% with latitude between the equator and the poles, with gravity increasing at higher latitudes due to the oblate shape of the Earth. Thus precision regulator clocks used for celestial navigation in the early 20th century had to be recalibrated when moved to a different latitude.

Torsion pendulum

Also called torsion-spring pendulum, this is a wheel-like mass (most often four spheres on cross spokes) suspended from a vertical strip (ribbon) of spring steel, used as the regulating mechanism in torsion pendulum clocks. Rotation of the mass winds and unwinds the suspension spring, with the energy impulse applied to the top of the spring. The main advantage of this type of pendulum is its low energy use; with a period of 12–15 seconds, compared to the gravity swing pendulum's period of 0.5—2s, it is possible to make clocks that need to be wound only every 30 days, or even only once a year or more. Since the restoring force is provided by the elasticity of the spring, which varies with temperature, it is more affected by temperature changes than a gravity-swing pendulum. The most accurate torsion clocks use a spring of elinvar which has low temperature coefficient of elasticity.

A torsion pendulum clock requiring only annual winding is sometimes called a "400-Day clock" or "anniversary clock", sometimes given as a wedding gift. Torsion pendulums are also used in "perpetual" clocks which do not need winding, as their mainspring is kept wound by changes in atmospheric temperature and pressure with a bellows arrangement. The Atmos clock, one example, uses a torsion pendulum with a long oscillation period of 60 seconds.

Escapement

The escapement is a mechanical linkage that converts the force from the clock's wheel train into impulses that keep the pendulum swinging back and forth. It is the part that makes the "ticking" sound in a working pendulum clock. Most escapements consist of a wheel with pointed teeth called the escape wheel which is turned by the clock's wheel train, and surfaces the teeth push against, called pallets. During most of the pendulum's swing the wheel is prevented from turning because a tooth is resting against one of the pallets; this is called the "locked" state. Each swing of the pendulum a pallet releases a tooth of the escape wheel. The wheel rotates forward a fixed amount until a tooth catches on the other pallet. These releases allow the clock's wheel train to advance a fixed amount with each swing, moving the hands forward at a constant rate, controlled by the pendulum.

Although the escapement is necessary, its force disturbs the natural motion of the pendulum, and in precision pendulum clocks this was often the limiting factor on the accuracy of the clock. Different escapements have been used in pendulum clocks over the years to try to solve this problem. In the 18th and 19th centuries, escapement design was at the forefront of timekeeping advances. The anchor escapement (see animation) was the standard escapement used until the 1800s when an improved version, the deadbeat escapement, took over in precision clocks. It is used in almost all pendulum clocks today. The remontoire, a small spring mechanism rewound at intervals which serves to isolate the escapement from the varying force of the wheel train, was used in a few precision clocks. In tower clocks the wheel train must turn the large hands on the clock face on the outside of the building, and the weight of these hands, varying with snow and ice buildup, put a varying load on the wheel train. Gravity escapements were used in tower clocks.

By the end of the 19th century specialized escapements were used in the most accurate clocks, called astronomical regulators, which were employed in naval observatories and for scientific research. The Riefler escapement, used in Clemens-Riefler regulator clocks was accurate to 10 milliseconds per day. Electromagnetic escapements, which used a switch or phototube to turn on a solenoid electromagnet to give the pendulum an impulse without requiring a mechanical linkage, were developed. The most accurate pendulum clock was the Shortt-Synchronome clock, a complicated electromechanical clock with two pendulums developed in 1923 by W.H. Shortt and Frank Hope-Jones, which was accurate to better than one second per year. A slave pendulum in a separate clock was linked by an electric circuit and electromagnets to a master pendulum in a vacuum tank. The slave pendulum performed the timekeeping functions, leaving the master pendulum to swing virtually undisturbed by outside influences. In the 1920s the Shortt-Synchronome briefly became the highest standard for timekeeping in observatories before quartz clocks superseded pendulum clocks as precision time standards.

Time indication

The indicating system is almost always the traditional dial with moving hour and minute hands. Many clocks have a small third hand indicating seconds on a subsidiary dial. Pendulum clocks are usually designed to be set by opening the glass face cover and manually pushing the minute hand around the dial to the correct time. The minute hand is mounted on a slipping friction sleeve which allows it to be turned on its arbor. The hour hand is driven not from the wheel train but from the minute hand's shaft through a small set of gears, so rotating the minute hand manually also sets the hour hand.

Maintenance and Repair

Pendulum clocks are long lived and don't require a lot of maintenance, which is one reason for their popularity.

As in any mechanism with moving parts, regular cleaning and lubrication is required. Specific low viscosity lubricants have been developed for clocks, one of the most widely used being a polyalcanoate synthetic oil.

Springs and pins may wear out and break and need replacing.

Styles

Pendulum clocks were more than simply utilitarian timekeepers; due to their high cost they were status symbols that expressed the wealth and culture of their owners. They evolved in a number of traditional styles, specific to different countries and times as well as their intended use. Case styles somewhat reflect the furniture styles popular during the period. Experts can often pinpoint when an antique clock was made within a few decades by subtle differences in their cases and faces. These are some of the different styles of pendulum clocks:

- Act of Parliament clock

- Anniversary clock (uses a torsion pendulum)

- Banjo clock

- Bracket clock

- Cartel clock

- Comtoise or Morbier clock

- Crystal regulator

- Cuckoo clock

- Grandfather clock

- Lantern clock

- Mantel clock

- Master clock

- Ogee clock

- Pillar clock

- Schoolhouse regulator

- Torsion pendulum clock

- Turret clock

- Vienna regulator

- Zaandam clock

See also

- Pendulum (mathematics)

- Cycloidal pendulum

- Flying pendulum clock

- Steam clock

- Balance spring (hairspring)

References

- ^ Milham, Willis I. (1945). Time and Timekeepers. New York: MacMillan. pp. 330, 334. ISBN 0-7808-0008-7.

- ^ Marrison, Warren (1948). "The Evolution of the Quartz Crystal Clock". Bell System Technical Journal. 27 (3): 510–588. doi:10.1002/j.1538-7305.1948.tb01343.x. Archived from the original on 2007-05-13.

- ^ a b c d Macey, Samuel L. (1994). Encyclopedia of Time. New York: Garland Publishing. ISBN 0815306156.

- ^ a b c d e f g h i j k Andrewes, W.J.H. Clocks and Watches: The leap to precision in Macey, Samuel (1994). Encyclopedia of Time. Taylor & Francis. pp. 123–125. ISBN 978-0-8153-0615-3.

- ^ "Huygens' Clocks". Stories. Science Museum, London, UK. Retrieved 2007-11-14.

- ^ "Pendulum Clock". The Galileo Project. Rice Univ. Retrieved 2007-12-03.

- ^ A modern reconstruction can be seen at "Pendulum clock designed by Galileo, Item #1883-29". Time Measurement. Science Museum, London, UK. Retrieved 2007-11-14.

- ^ Bennet, Matthew; et al. (2002). "Huygens' Clocks" (PDF). Georgia Institute of Technology. Archived from the original (PDF) on 2008-04-10. Retrieved 2007-12-04., p.3, also published in Proceedings of the Royal Society of London, A 458, 563–579

- ^ Headrick, Michael (2002). "Origin and Evolution of the Anchor Clock Escapement". Control Systems Magazine. 22 (2). Inst. of Electrical and Electronic Engineers. Archived from the original on October 25, 2009. Retrieved 2007-06-06.

- ^ Milham 1945, p. 190

- ^ Milham 1945, p.181, 441

- ^ Milham 1945, pp. 193–195

- ^ Milham 1945, p.83

- ^ "A Revolution in Timekeeping". Time and Frequency Services, NIST. April 30, 2002. Archived from the original on 2007-05-28. Retrieved 2007-05-29.

- ^ Sullivan, D.B. (2001). "Time and frequency measurement at NIST: The first 100 years" (PDF). 2001 IEEE Int'l Frequency Control Symp. National Institute of Standards and Technology. Archived from the original (PDF) on 2011-09-27.

- ^ Jones, Tony (2000). Splitting the Second: The Story of Atomic Time. US: CRC Press. p. 30. ISBN 978-0-7503-0640-9.

- ^ Milham, Willis I. (1945). Time and Timekeepers. New York: MacMillan. p. 615.

- ^ Marrison, Warren (1948). "The Evolution of the Quartz Crystal Clock". Bell System Technical Journal. 27 (3): 510–588. doi:10.1002/j.1538-7305.1948.tb01343.x. Archived from the original on 2011-07-17.

- ^ "The Reifler and Shortt clocks". JagAir Institute of Time and Technology. Retrieved 2009-12-29.

- ^ Betts, Jonathan (May 22, 2008). "Expert's Statement, Case 6 (2008-09) William Hamilton Shortt regulator". Export licensing hearing, Reviewing Committee on the Export of Works of Art and Objects of Cultural Interest. UK Museums, Libraries, and Archives Council. Archived from the original (DOC) on October 25, 2009. Retrieved 2009-12-29.

- ^ Audoin, Claude; Bernard Guinot; Stephen Lyle (2001). The Measurement of Time: Time, Frequency, and the Atomic Clock. UK: Cambridge Univ. Press. p. 83. ISBN 0-521-00397-0.

- ^ Kennedy, Maev (May 7, 2003). "Scientist's historic clock collection for sale". The Guardian. London: Scott Trust Ltd. Retrieved March 18, 2017.

- ^ Mumford, Bryan (November 2005). "Some thoughts on the Littlemore clock" (PDF). Horological Science Newsletter. National Assoc. of Watch and Clock Collectors: 20–22. Retrieved March 18, 2017.

- ^ Hall, E.T. (June 1996). "The Littlemore Clock". Horological Science. Nat'l Assoc. of Watch and Clock Collectors. pp. fig. 7b.

- ^ Guilbaud, Gérard. "Genève [Geneva]" (in French). Patrimoine-Horloge. Retrieved February 11, 2024.

- ^ Gierszewski, Andrzej (June 29, 2023). "Rusza konkurs na nową nazwę dla rekordowego zegara z Muzeum Nauki Gdańskiej [A competition for a new name for the record clock from the Gdańsk Science Museum is starting]" (Press release) (in Polish). Gdańsk Museum. Retrieved February 11, 2024.

- ^ Milham 1945, pp. 74, 197–212

- ^ Arnstein, Walt. "The Gravity Pendulum and its Horological Quirks". Community Articles. Timezone.com website. Archived from the original on 2013-02-04. Retrieved 2011-04-01.

- ^ Gore, Jeff; Alexander van Oudenaarden (January 15, 2009). "The Yin and Yang of Nature" (PDF). Nature. 457 (7227). MacMillan: 271–2. Bibcode:2009Natur.457..271G. doi:10.1038/457271a. PMID 19148089. S2CID 205043569. Retrieved 2009-07-22.