Clinker (boat building)

Clinker-built, also known as lapstrake-built,[1][2] is a method of boat building in which the edges of longitudinal (lengthwise-running) hull planks overlap each other. Where necessary in larger craft, shorter hull planks can be joined end to end, creating a longer hull plank (strake).[not verified in body]

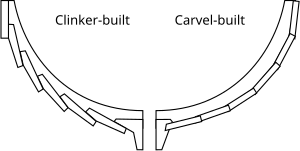

The technique originated in Nordic shipbuilding, and was employed by the Anglo-Saxons, Frisians, and Scandinavians.[when?][not verified in body] It was also used in cogs, the other major ship construction type found in Northern Europe in the latter part of the medieval period. Carvel construction—where longitudinal hull planks abut edge to edge (instead of lapping)—supplanted clinker construction in large vessels as the demand for capacity surpassed the limits of clinker construction, such as in larger medieval transport ships (hulks).[3]

UNESCO named the Nordic clinker boat tradition to its List of Intangible Cultural Heritage on December 14, 2021, in the first approval of a joint Nordic application.[4]

Description

Clinker construction is a boat and ship-building method in which the hull planks overlap and are joined by nails that are driven through the overlap. These fastenings typically go through a metal rove over which the protruding end of the nail is deformed in a process comparable to riveting the planks together. This gives a distinctive appearance to the outside of the hull as the overlaps are obvious in the stepped nature of the hull surface.[5]: 53–54 [6]: 10–11

Clinker construction is a shell-first technique (in contrast to the frame-based nature of carvel). The construction sequence begins with the joining of the keel, stem and sternpost (or transom) and setting these in place in the build area. Thereafter, the shape of the hull is determined by the shaping and fitting of the hull planking that forms the waterproof exterior of the hull. Any reinforcing frames, thwarts or beams[a] are added after the joining of the hull planks. This may involve completely finishing the exterior planking first, or just some planking may be fitted with, for instance, floors being added whilst that part of the hull is accessible before planking is continued.[5]: 53–54

Medieval clinker construction used iron nails and roves – the latter often being a distinctive diamond shape. There are less common regional instances of planks being joined with treenails or by sewing, but iron fastening predominated.[5]: 54 More modern boats generally use copper nails with an annular rove of the same material.[7]: 25

Historically, particularly in the traditional Nordic tradition[b], clinker construction most commonly used cleft, or radially split, oak planks. This gives a stronger piece of timber than with sawn material – not only is the grain continuous along the length of the piece, but the medullary rays are aligned in the same plane as the timber surface, so maximising the strength available. However, this timber conversion method does limit the maximum width of plank to slightly more than one third of the diameter of the tree from which it is split – the narrowest part (including any pith) and the sapwood are cut off.[5]: 53–54, 60 [9] The slightly uneven surface found on cleft timber is the reason why caulking is laid in the overlap between the hull planks during construction, often using animal hair.[8]

Examples

Early examples of clinker-built boats include the longships of the Viking raiders and traders,[when?] and the trading cogs of the Hanseatic League.[when?][citation needed] Modern examples of clinker-built boats that are directly descended from those of the early medieval period are seen in the traditional round-bottomed Thames skiffs, the larger (originally) cargo-carrying Norfolk wherries of England,[10] and working craft like the yawls that were once common around the coasts of Britain and Ireland.[11]: passim

History

The term clinker derives from a common Germanic word for clinch or clench, a word meaning “to fasten together”.[12]

Historical context: other systems

In the first few centuries AD, several boat and ship-building systems existed in Europe. In the Mediterranean, flush-planked hulls were produced by edge-to-edge joining of the hull planking with mortise and tenon joints. This was a shell-first technique[c], which started with a keel, stem and stern-post, to which planking was added. The hull was then reinforced by the addition of frames. The shape of the individual planks generates the shape of the hull. In the Roman-occupied parts of Northern Europe, the Romano-Celtic tradition involved flush-planking that was not joined with mortise and tenon joints but was connected by framing elements. (This may be a building tradition that continued with the bottom planking of the medieval cog and then into the Dutch bottom-based building methods of the 17th century.) The Romano-Celtic method of construction is also a shell-first technique, in that the hull shape is dictated by the shaping of the planks, not by the underlying framing of the finished hull.[5]: ch 4

Origins of clinker

There are precursors of clinker construction. The archaeological remains of a river boat dated to the first two centuries AD (described as Romano-Celtic), found in Pommeroeul in Belgium, had a single strake that overlapped the underlying plank – though it is not clear how it was fastened. Earlier finds have bevelled lap joints or other similar arrangements that do not have the full lap of clinker. These include the Dover boat and Ferriby 1 (both dating to the middle of the second millennium BC) and the Hjortspring boat (c. 300-350 BC). In these cases, the planks are stitched or sewn together. The Hjortspring boat is built shell-first so suggesting some continuity with the Nordic tradition of clinker construction.[13]: 201, 207–210 [5]: 63-66

The earliest example of ship and boat building using overlapped planking joined with metal fastenings is in an extended logboat from Björke in Sweden. This dates to c. 310 AD. The Nydam boat is an almost complete example of a boat built with clinker construction. It has overlapping planks joined with iron nails driven through the lap. The nails are clenched over roves on the inside of the planking. The boat was built shell-first. It dates to c. 320 AD.[5]: 63-66 [13]: 210-211

Into the medieval

Though clinker construction is closely associated with Nordic countries, the same technique was used at an early stage in other parts of Northern Europe. The Saxon burial ship at Sutton Hoo in eastern England is an early (c. AD 630) example of this sort of ship occurring in the broader Northern European area. Other sites from the 7th century AD include Kvalsund, Norway, Gretstedbro in Jutland and Snape in eastern England. One difference from the Nydam boat is that individual planks in the later period are shorter and narrower. This suggests that large oak trees for ship-building had become a lot less common by the 7th century, so timber of smaller dimensions had to be used.[5]: 65 [13]: 207-210

The 8th, 9th and 10th centuries saw the use of Viking longships for raiding and settlement. Archaeological remains of these clinker-built ships include the Oseberg ship and the Gokstad ship. These show some development from earlier vessels, including a partial keelson which acted as the mast step. As well as these warship types, cargo vessels were built which were less extreme with greater beam and more emphasis on propulsion by sail, together with extra cross-beams to strengthen the hull for greater weight carrying.[13]: 212-217

The cog is part of another ship-building tradition in Northern Europe that existed at the same time that the purely Nordic-tradition clinker vessels were being built. Though the classic cog construction uses flush planking for the bottom, the sides are constructed in a clinker method – with the difference that the nails that passed through overlapping planks were simply bent over and driven back into the plank, rather than using roves.[5]: 66

Clinker-built vessels were constructed as far South as the Basque country; the Newport Medieval Ship is an example of a clinker-built vessel that was built in the Basque region.[14][15] By the 14th century, clinker-built ships and the cog represented the major construction methods in Northern Europe.[5]: 66

Introduction of carvel to Northern Europe

Carvel construction was developed in the Mediterranean around the end of the Classical antiquity period.[d] By the end of the 13th century AD, Mediterranean ships were being built on a skeleton basis, with hull planks being fixed to the frames and not to each other. At the same time, Northern European cogs were voyaging into the Mediterranean. The two maritime technological traditions had differences beyond the hull construction methods. Mediterranean ships were carvel-built, lateen rigged (using more than one mast on larger vessels) and still used side rudders. The visiting cogs had a single square-rigged mast, a stern-post mounted pintle-and-gudgeon rudder and clinker sides. As part of the process of merging these two sets of traditions, carvel-built ships started to arrive in Northern waters. They were soon followed by shipwrights with the skills to build in carvel construction, with the first being built in this region in the late 1430s. The change is still not well understood. The frames of carvel could be made stronger to support the weight of the guns that ships were starting to carry and allowed gun-ports to be cut in the hull. Carvel construction may have solved the shortage of large cleft oak planks from which to make larger clinker vessels.[5]: 50, 58-60, 69-72 Despite the large-scale move over to carvel construction for large vessels, clinker construction remained prominent throughout Northern Europe.

The Nordic clinker boat tradition was inscribed to the UNESCO List of the Intangible Cultural Heritage on December 14, 2021, as the first joint Nordic application to the list.[4]

- Clinkered prow of the Viking Oseberg ship.[citation needed]

- Clinker-type lapped iron plating on the lower hull of the historic, record-setting SS Great Britain (launched 1845).[16][17][18]

Construction

Planking

In the clinker- (lapstrake-[1][2]) method of boat building, the edges of longitudinal hull planks overlap each other.[citation needed] Where necessary in larger craft, shorter planks can be joined end to end, creating a longer strake or hull plank.[citation needed]

How this is done is as follows.[according to whom?] In building such a boat (e.g., a simple pulling boat), workers assemble and securely set up the keel,hog stem,apron, deadwoods, sternpost and perhaps transom.[citation needed][e] In normal practice, this will be the same way up as they will be in use. From the hog, the garboard, bottom, bilge, topside and sheer strakes are planked up, held together along their ‘lands’ – the areas of overlap between neighbouring strakes – by copper rivets. At the stem and, in a double-ended boat, the sternpost, geralds are formed. That is, in each case, the land of the lower strake is tapered to a feather edge at the end of the strake where it meets the stem or stern-post. This allows the end of the strake to be screwed to the apron with the outside of the planking mutually flush at that point and flush with the stem. This means that the boat's passage through the water will not tend to lift the ends of the planking away from the stem. Before the next plank is laid up, the face of the land on the lower strake is bevelled to suit the angle at which the next strake will lie in relation with it. This varies all along the land. Gripes are used to hold the new strake in position on the preceding one before the fastening is done.

Timbering or framing out

How thes steps are done is as follows.[according to whom?] Once the shell of planking is assembled, transverse battens of oak, ash, or elm, called timbers, are steam-bent to fit the internal, concave side.[f] As the timbers are bent in, they are fastened to the shell (e.g., via copper-riveting), through the lands of the planking. Alternatively, as on many clinker-built craft, e.g. in Scandinavia and in Thames skiffs and larger working craft like the coble, sawn frames are used, assembled from floors and top timbers, joggled to fit the lands. (Sometimes the timbers in larger archaic craft were also joggled before being steamed in.)

With the timbers all fitted, longitudinal members are bent in.[citation needed] The ones that run on the underside of the thwarts are called risings.[19]: 211 They are fastened through the timbers. Bilge keels are often added to the outside of the land on which the boat would lie on a hard surface to stiffen it and protect it from wear. A stringer is usually fitted round the inside of each bilge to strengthen it. In a small boat, this is usually arranged to serve also as a means of retaining the bottom boards. These are removable assemblies, shaped to lie over the bottom timbers and be walked upon. They spread the stresses from the crew's weight across the bottom structure.

Longitudinals

Inboard of the sheer strake the heavier gunwale is similarly bent in along the line of the sheer. This part of the work is finished by fitting the breast hook and quarter knees. Swivel or crutch chocks are fitted as appropriate to the gunwale, the thwarts fitted down onto the rising and held in position by knees up to the gunwale and perhaps down onto the stringer. The structure of gunwale, rising, thwart and thwart knees greatly stiffens and strengthens the shell and turns it into a boat. There are several ways of fixing the rubbing strake, but, in a clinker boat, it is applied to the outside of the sheer strake.

Fittings and finishing

Fittings such as swivels or crutch plate, painter ring, stretchers, keel and stem band are fitted. In a sailing dinghy, there would be more fittings, such as fairleads, horse, shroud plates, mast step, toe straps and so on.

At stages along the way, painters will have been called in to prime the timber, particularly immediately before the timbering is done. The boatbuilder will clean up the inside of the planking and the painter will prime it and probably more, partly because it is easier that way and partly so as to put some preservative on the planking behind the timbers. Similarly, it is best to have the varnishing done after the fittings are fitted but before they are shipped. Thus, the keel band will be shaped and drilled and the screw holes drilled in the wood of keel and stem then the band will be put aside while the varnishing is done.

Fastenings

In general

The fittings of a clinker boat, as described above (keel, stem band, etc.) are fixed with screws.[citation needed] The planks of the boat may be fastened together in several ways:

- With copper or iron rivets[citation needed]—consisting of a square nail and a dish-shaped washer called a rove. The land is pierced, the nail knocked through from the outside, the rove punched on while the head is held up by a dolly (a small portable anvil, usually of cylindrical shape). The nail is cut off just proud of the rove and the cut end clenched[g] over the rove while the dolly is used to hold the nail in place. In planking up clinker work, one man can hold both dolly and clenching hammer. Although this is common where sawn frames are to be used, boats intended for steamed timbers are usually nailed but not clenched until the timbering out is complete. As timbering is a two-handed job it is more efficient to leave the clenching until help is at hand, and then the helper dollies up, whilst the builder sits inside the hull and clenches up.

- With iron nails[citation needed]—with the pointed nail ends protruding on the inside of the boat, bent over and back into the wood in the form of a hook. This technique, called clinching, used to be found in Scandinavian-built boats, but even iron nails on the lands were usually properly clenched over roves. Nails fastening timbers were sometimes turned over, particularly where removable bottom boards were to rest on the timbers. However, it was possible to tread the bottom boards onto the clenched nails and, where marks were left, gouge out recesses to accommodate the clenched nails.

- With screws[citation needed]—which may be used for fixing the ends of the strakes to the apron and transom. In later times, they also fixed knees to the gunwale and thwarts, but, traditionally, this last would be done with a clench bolt or a large copper nail, clenched.

- With adhesive, notably epoxy[citation needed]—where, traditionally, lands were not glued nor was anything used to bed them. The garboard was bedded onto the hog and keel and the ends of the strakes onto the stem and apron with a mixture of white lead and grease. During the world wars of the 20th century, new techniques and materials were developed by the aircraft industry. By the mid-1950s, these were well infiltrated into the boatbuilding trade. New boats in classes of racing dinghy with clinker hulls were built as glued clinker boats. The basic construction was the same as before, but they were built with decks of ply planking, and the lands were glued with no fastenings, except that the ends and garboards were still screwed to the apron and hog. Since plywood would not split, no timbers were used. Except for a light gunwale and wide rubbing strake, the longitudinals were omitted too, and a short thwart rising and knees were glued to the planking. Their decks made such boats sufficiently stiff. So that the liquid glue could be laid onto the land before the next plank was assembled onto it, the boats were built upside down.

Of the centre-line

Where suitable metal was not available, it was possible to use treenails (pronounced trennels), fasteners like clench bolts but made of wood; instead of being clenched, they had a hardwood wedge knocked into each end to spread it, after which, the surplus was then sawn off.[citation needed] In the last few years of wooden boat construction, glue and screws took over, but until the 1950s, the keel, hog, stem, apron, deadwoods, sternpost, and perhaps transom would be fastened together by bolts set in white lead and grease.[citation needed] There are three kinds of bolt used:

- The screw bolt (i.e. threaded bolt), with its nut and washer, is by far the most common.[citation needed]

- The pin bolt or cotter bolt, instead of a thread, has a tapered hole forged through the end away from the head, into which a tapered pin or cotter is knocked. The taper is in effect a straight thread. In conjunction with a washer, this draws the bolt tight, as a nut does on a screw bolt.[citation needed]

- The clench bolt has some of the features of a rivet but is usually much longer than the normal rivet; in a wooden ship, perhaps a metre or more. For a shipwright's use, it is of copper. A head is formed by upsetting one end using a swage. It is then knocked through a hole bored through the work to be fastened, and through a washer. The head is held up with a dolly and the other end is upset over the washer in the same way as the head.[20]

Until well into the nineteenth century, this is what held the great ships of the world together, though some such bolts may have been of iron.[citation needed] Until the late 1950s, the centre-line assembly of British Admiralty twenty-five foot motor cutters were fastened in this way.[citation needed]

Clinker and carvel compared

The Vikings used the clinker form of construction to build their longships from split wood planks. Clinker is the most common English term for this construction in both British and American English, though in American English the method is sometimes also known as lapstrake;[1][2] lapboard was used especially before the 20th century to side buildings, where the right angles of the structure lend themselves to quick assembly.[citation needed]

The smoother surface of a carvel boat gives the impression at first sight that it is hydrodynamically more efficient. The lands of the planking are not there to disturb the stream line. This distribution of relative efficiency between the two forms of construction is an illusion because for given hull strength, the clinker boat is lighter.[citation needed]

Additionally, the clinker building method as used by the Vikings created a vessel which could twist and flex relative to the line extending length of the vessel, bow to stern. This gave it an advantage in North Atlantic rollers so long as the vessel was small in overall displacement. Increasing the beam, due to the light nature of the method, did not commensurately increase the vessel's survivability under the torsional forces of rolling waves, and greater beam widths may have made the resultant vessels more vulnerable.[citation needed]

There is an upper limit to the size of clinker-built vessels, which could be and was exceeded by several orders of magnitude in later large sailing vessels incorporating carvel-built construction. Clinker building requires relatively wide planking stock compared to carvel, as carvel can employ stealers to reduce plank widths amidships, where their girth is greatest, while clinker planks, needing sufficient lap to accept their clench fastenings, must be wider in proportion to their thickness. In all other areas of construction, including framing, deck, etc., clinker is as capable as carvel. Clinker construction remains to this day a valuable method of construction for small wooden vessels.[citation needed]

See also

Notes

- ^ In some early instances, beams were notched over the planks, so they had to be installed before the next strake was added. This design was replaced by fastening beam ends to other framing components that spread the load better over the hull surface.

- ^ Nordic clinker construction has been categorised into "traditional" and "modern". These two styles originate from increasing change in the details of clinker construction, starting from the 13th century onwards, but with the traditional remaining in use in the Northern part of Scandinavia, where there was limited urbanisation and little trade to continental Europe. Conversely, the modern tradition adopted ship-building practices that were influenced by contact from outside Scandinavia. Use of sawn planking is an example.[8]

- ^ Other descriptive terms for the same concept include "plank orientated", "planking first", etc,

- ^ The shipbuilding changes in the Mediterranean region once appeared to be a simple and steady transition away from the mortise and tenon edge-joined hull planking to carvel. As more archaeological finds have been investigated, the evidence suggests that this was not a linear developmental process.

- ^ Hog: a longitudinal piece of timber fastened directly on top of the keel; the garboard planks (those closest to the keel) are fastened to the hog.[19]: 211, 215

Apron: a curved piece of timber fastened on the inside of the stem and onto the top of the front part of the keel; sometimes similarly to the sternpost and after part of the keel. The ends of the hull planks are fastened to the apron.[19]: 211, 213 - ^ Elm species are not durable where the boat is used frequently in fresh water.[citation needed]

- ^ Some people[weasel words] pronounce this word as "clinched," an example of regional variation in boatbuilding terms.[citation needed]

References

- ^ a b c Webb, Michael. "Clinker Boat History & Building". Wootton Bridge Industries. Archived from the original on 2008-12-02.

- ^ a b c "Lapstrake". Danenberg Boatworks. Retrieved 2020-02-13.

- ^ Lewis, Marcus & TMS Staff (2013-05-08). "Clinker and Carvel—Different Types of Planking". Boat-Building.org. Falmouth, Cornwall, England (and other): Traditional Maritime Skills (TMS). Archived from the original on 2013-05-08. Retrieved 2015-02-10.

- ^ a b Marsio, Leena & FHA Staff (2021-12-14). "Nordic Clinker Boat Tradition Inscribed to UNESCO List of the Intangible Cultural Heritage". Museovirasto.fi. Helsinki, Finland: Museovirasto (Finnish Heritage Agency (FHA). Retrieved 2024-11-17.

- ^ a b c d e f g h i j k Adams, Jonathan (2013). A maritime archaeology of ships: innovation and social change in late medieval and early modern Europe. Oxford: Oxbow Books. ISBN 9781782970453.

- ^ Vinner, Max (2013). Boats of the viking ship museum. Roskilde: Viking Ship Museum. ISBN 978-87-85180-63-6.

- ^ Leather, John (1973). Clinker Boatbuilding. London: Adlard Coles Limited. ISBN 0-229-11504-7.

- ^ a b Bill, Jan (2006). "From Nordic to North European. Analysis in the study of changes in Danish shipbuilding A.D. 900 to 1600". In Bockius, Ronald (ed.). Between the Seas. Transfer and Exchange in Nautical Technology. Proceedings of the Eleventh International Symposium on Boat and Ship Archaeology, Mainz 2006. doi:10.13140/2.1.5120.3204.

- ^ Gawronski, Jerzy; Holk, André van; Schokkenbroek, Joost (2017-09-25). Ships And Maritime Landscapes: Proceedings of the Thirteenth International Symposium on Boat and Ship Archaeology, Amsterdam 2012. Barkhuis. p. 320. ISBN 978-94-92444-29-5.

- ^ "Clinker Boat Building". Hobby.net.au Australia. Archived from the original on 2023-01-21. Retrieved 2011-02-23.

- ^ Mannering, Julian; Greenhill, Basil, eds. (2013) [1997]. Inshore Craft, Traditional Working Vessels of the British Isles. Barnsley: Seaforth Publishing. ISBN 978-1-84832-167-0.

- ^ Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica. Vol. 6 (11th ed.). Cambridge University Press. p. 527.

- ^ a b c d McGrail, Seán (2009). Boats of the world: from the stone age to medieval times (Reprinted ed.). Oxford New York: Oxford University Press. ISBN 978-0199271863.

- ^ Nayling, Nigel; Jones, Toby (September 2014). "The Newport Medieval Ship, Wales, United Kingdom: The Newport Medieval Ship". International Journal of Nautical Archaeology. 43 (2): 239–278. doi:10.1111/1095-9270.12053. S2CID 108922370. Retrieved November 17, 2024.

- ^ Nayling, Nigel; Susperregi, Josué (September 2014). "Iberian Dendrochronology and the Newport Medieval Ship: Iberian Dendrochronology and the Newport Medieval Ship". International Journal of Nautical Archaeology. 43 (2): 279–291. doi:10.1111/1095-9270.12052.

- ^ Corlett, Ewan (2005). The Iron Ship: The Story of Brunel's SS Great Britain (2nd (revised) ed.). London, England: Conway Maritime Press. pp. 27f. ISBN 0851775497. Retrieved November 17, 2024.

- ^ Farr, Grahame (1965). McGrath, Patrick; Harris, Peter (eds.). "The Steamship Great Britain". BHA pamphlets, no. 11. Bristol, England: Bristol Branch of the Historical Association, University of Bristol. pp. 1, 6f, and passim.

- ^ Per the description of this image at Wikimedia Commons, "clinker building wasn't a common choice [for iron-hulled vessels] for long. Although strong, it required a tapered (i.e. expensive) liner to be fitted beneath each plate to fit closely to the frames." See this link.

- ^ a b c Lords Commissioners of the Admiralty (1942) [1937]. "VIII. Boats. Part I. Boat Construction and Management Under Oars". Manual of Seamanship. Vol. I. London: Her Majesty's Stationery Office (HMSO). Retrieved 17 November 2024.

- ^ Zori, Davide (2007). "Nails, Rivers, and Clench Bolts: A Case for Typological Clarity". Archaeologia Islandica. 6: 32–47.

Further reading

- Greenhill, Basil (1976). Archaeology of the Boat. London, England: Adam and Charles Black Publishers Ltd. ISBN 9780713616453.[full citation needed]

- Greenhill, Basil & Morrison, John S. (1995). The Archaeology of Boats and Ships: An Introduction. London, England: Conway Maritime Press. ISBN 9781557500397.

{{cite book}}: CS1 maint: multiple names: authors list (link)[full citation needed] - Leather, John (1990). Clinker Boatbuilding. London, England: Bloomsbury-Adlard Coles. ISBN 9780713636437.[full citation needed]

- McKee, Eric (1972). Clenched Lap or Clinker: An Appreciation of a Boatbuilding Technique. Greenwich, England: National Maritime Museum.[full citation needed]

![Clinker hull of the Nydam Boat from Jutland.[citation needed]](https://upload.wikimedia.org/wikipedia/commons/thumb/c/c1/Nydamboat.2.jpg/120px-Nydamboat.2.jpg)

![Clinkered prow of the Viking Oseberg ship.[citation needed]](https://upload.wikimedia.org/wikipedia/commons/thumb/2/2b/Exhibition_in_Viking_Ship_Museum%2C_Oslo_01.jpg/90px-Exhibition_in_Viking_Ship_Museum%2C_Oslo_01.jpg)

![Clinker-built medieval cog from Stralsund.[citation needed]](https://upload.wikimedia.org/wikipedia/commons/thumb/0/04/Kogge_stralsund.jpg/120px-Kogge_stralsund.jpg)

![Clinker-type lapped iron plating on the lower hull of the historic, record-setting SS Great Britain (launched 1845).[16][17][18]](https://upload.wikimedia.org/wikipedia/commons/thumb/c/c9/Clinker_built_iron_plating%2C_SS_Great_Britain.jpg/120px-Clinker_built_iron_plating%2C_SS_Great_Britain.jpg)